33 Buckets: Human-Centered Design in Chlorine Disinfection

Since our first project in the Cusco region of Peru, we have been employing the human-centered design approach to improve our clean water solutions. In 2018, our team of engineers determined that we could sustainably create access to clean water for the most people in the region by implementing an improved version of their existing treatment method: chlorine disinfection. Done right, this technique is proven to be one of the most effective long-term solutions to creating clean drinking water.

What is Chlorine Disinfection?

Chlorine disinfection, or chlorination, is a water treatment process in which chlorine is added to drinking water. When applied, chlorine disinfectants form “free chlorine,” which destroys pathogenic (disease-causing) bacteria [1]. There are several benefits to choosing chlorination as a means of creating safe drinking water:

The Benefits of Chlorine

Potent Germicide

Chlorine disinfectants can reduce the level of many disease-causing microorganisms in drinking water to almost immeasurable levels.

Taste and Odor Control

Chlorine disinfectants reduce many disagreeable tastes and odors. Chlorine oxidizes many naturally occurring substances such as foul-smelling algae secretions, sulfides and odors from decaying vegetation.

Biological Growth Control

Chlorine disinfectants eliminate slime bacteria, molds, and algae that commonly grow in water supply reservoirs, on the walls of water mains, and in storage tanks.

Chemical Control

Chlorine disinfectants destroy hydrogen sulfide (which has a rotten egg odor) and remove ammonia and other nitrogenous compounds that have unpleasant tastes and hinder disinfection. They also help to remove iron and manganese from raw water.

Chlorination is an incredibly powerful tool, but it requires proper operation to produce clean water at all times. Precision is key -- inaccurate dosing can prevent effective treatment, allowing water-related illnesses to ensue. Testing methods are often subjective and time-intensive. Additionally, dosing methods are often not quantifiable and are subject to external variables like seasonal flow rate. Put that together, and the treatment demands a great deal of effort from local water managers in our partner communities (who often work on a volunteer basis) to appropriately operate these chlorine disinfection systems.

What if we could make the process much more efficient and user-friendly? And what if, at the same time, we significantly reduced the necessary cost by limiting ourselves to materials that are widely available in Peru?

To do just that, we launched a team within Engineering Projects In Community Service, or EPICS, at Arizona State University.

EPICS is an engineering, design-based service learning & social entrepreneurship program that gives undergraduate students an opportunity to build solutions to real-world problems. Through the program, students practice the human-centered design process in a team environment, working with local or global community partners with a focus on either community development, health, sustainability, and/or education. Collaborating with EPICS in the realm of research & development benefits the efficiency of our projects while also giving participants a project to practice and grow in many of the skills that will lead to success in life beyond college. Better yet, because teams are multidisciplinary and composed of a mix of freshmen through senior students, we can guarantee that there are multiple perspectives contributing throughout the design process.

In early 2019, our student interns formed an EPICS team of 7 undergraduate engineers with the goal of designing and prototyping an improved chlorine disinfection for use in 33 Buckets’ clean water projects in Cusco, Peru.

The team identified three main design criteria: (1) Continuous dosing, (2) Autonomous water quality testing, and (3) On-site and remote monitoring of residual chlorine levels.

Within a month, our student team constructed a prototype for both a dosing mechanism and a residual chlorine sensor. They pitched their design at the first ever EPICS Elite Pitch Competition in which they were awarded first place and $1,500 for further development of the prototypes. That semester, the team focused on iterating the chlorine sensor through experimental testing. The following summer, three of our student team members traveled to Cusco to support the implementation of 33 Buckets’ first chlorine disinfection system.

While we have continuously collected feedback and improved our design, the first chlorination system that the EPICS team implemented is still producing clean water for over 1,200 residents in Occopata, Peru.

Improving the Design

Our first prototype did what it needed to do: it increased the effectiveness of chlorine disinfection over systems that had been previously used, while utilizing materials that could be sourced locally. Nevertheless, there remained room for improvement. 5 main limitations were identified:

The valves did not have markers to quantify dosing

There were no valves for cleaning/draining the system

The cap for the chlorination tube was often difficult to remove

The system must be installed on top of a reservoir

There was relatively less mixing within the chlorinator unit in comparison to other chlorinators available for purchase, such as Water Mission's Erosion Chlorinator

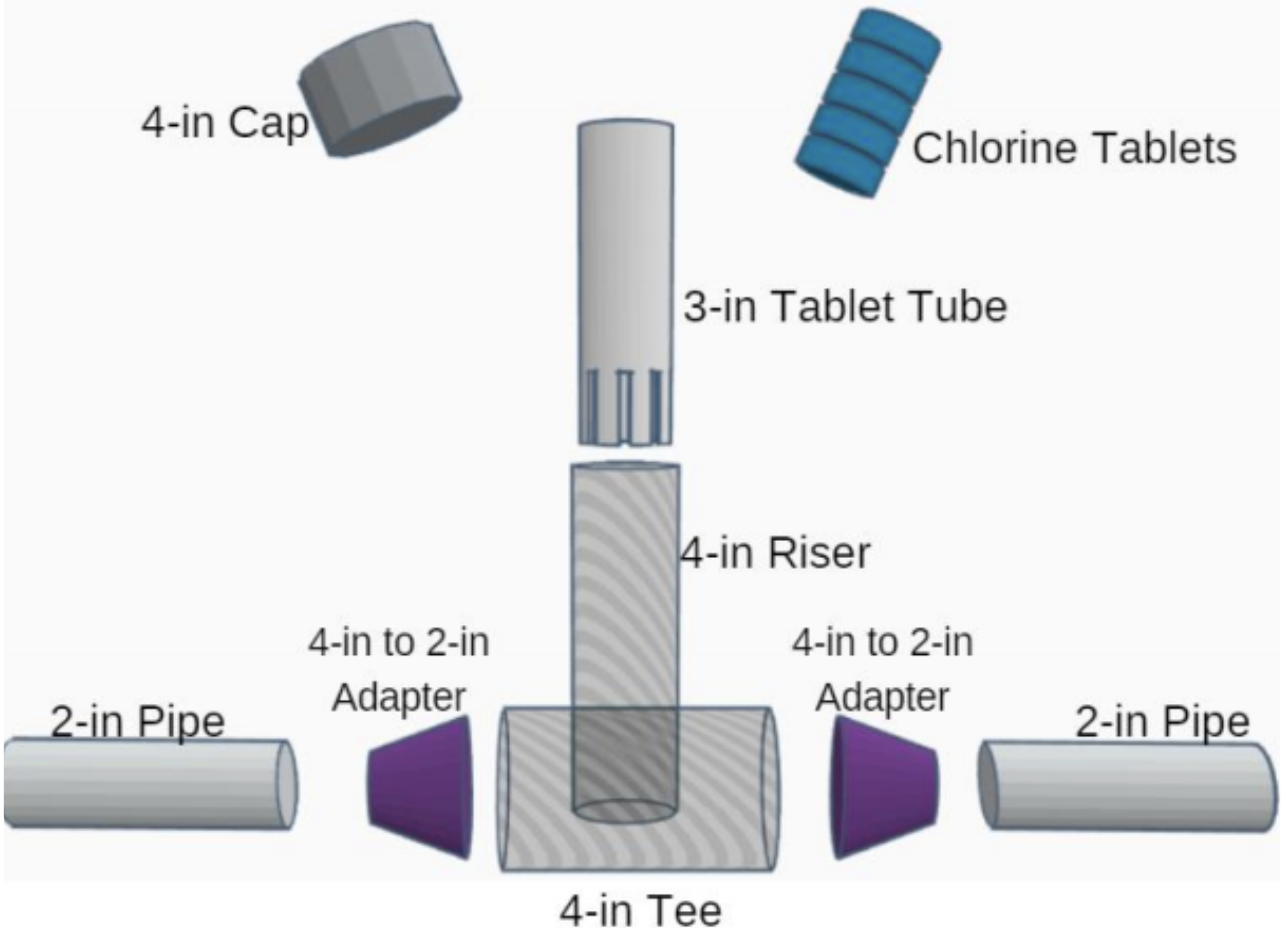

In the beginning of 2020, 33 Buckets’ student research program expanded to three EPICS teams focusing on the three respective criteria for our chlorine disinfection system that were identified earlier. With a specific area of focus, we believe that each team is set to discover a more sustainable, effective, and innovative design for each component. Together, these teams are constructing a new-and-improved method of water treatment: 33 Buckets’ Autonomous Chlorination System

Design Requirements for EPICS’ autonomous chlorination system

Provide continuous and consistent exposure to chlorine

Enable quantifiable dosing valves with markings

Allow for efficient, effective draining and cleaning

Enable easy removal of "chlorination cap" to replenish chlorine tablets

Allow for retrofitting of autonomous chlorine sensor system

At a minimum, hold 5 tablets

EPICS Chlorine Injection Team

Simulation of water flowing through a large chlorination tank (to test effect of holding 25+ chlorine tablets)

The chlorine injection team is redesigning the body of the chlorine disinfection system to…

Continuously chlorinate a community’s water source

Allow for easy automatic adjustments to the chlorine concentration

Decrease the required frequency of replenishing chlorine tablets

EPICS Sensor Development Team

The sensor development team has been working to create a chlorine sensor capable of…

Continuously collecting accurate, numerical chlorine concentrations at the point of monitoring

Displaying, recording, and transmitting results of a chlorine analysis

Running off of solar power (available in the Cusco region

Testing a sensor prototype to measure differences in output with change in temperature.

EPICS Internet of Things Team (Monitoring & Data Collection)

The IoT team is programming a device that will…

Diagram showing how data is collected by and transmitted from an Iridium EdgeⓇ Pro device

Continuously communicate with the chlorine sensor to transmit data to a satellite network

Automatically record logs of residual chlorine data

Make residual chlorine data accessible in real-time

Runoff of solar power (available in the Cusco region)

What’s next?

This summer, our on-the-ground team will be performing field testing of our newest sensor prototype and assessing the feasibility of using the Iridium EdgeⓇ Pro for remote data storage and collection. We are continuing to collaborate closely with our local partner, Sustainable Development Studies in Peru (SDS), to improve effectiveness and decrease costs of our chlorine dosing mechanism using only local materials.

We are incredibly thankful for the role that our EPICS students have had in bringing us closer to creating a scalable, human-centered solution to water treatment in underserved communities!

Resources